Quality Control

Quality is the core of every successful faucet brand. At Faucetri , we follow a strict, multi-stage quality control system to ensure every faucet meets international standards in performance, durability, and safety. Below you will find a comprehensive guide to understanding how we maintain exceptional faucet quality from raw materials to final shipment.

Procedure: step by step quality assessment

Incoming Inspection

Verify supplier documents, material certificates (composition, heat treatment, RoHS, etc.), and batch numbers.

Perform sampling tests to confirm chemical composition and material grade (e.g., brass grades, 304/316 stainless steel).

Inspect key components—such as cartridges, sealing rings, and ceramic discs—for appearance and dimensional accuracy.

FDA(U.S. Food and Drug Administration)

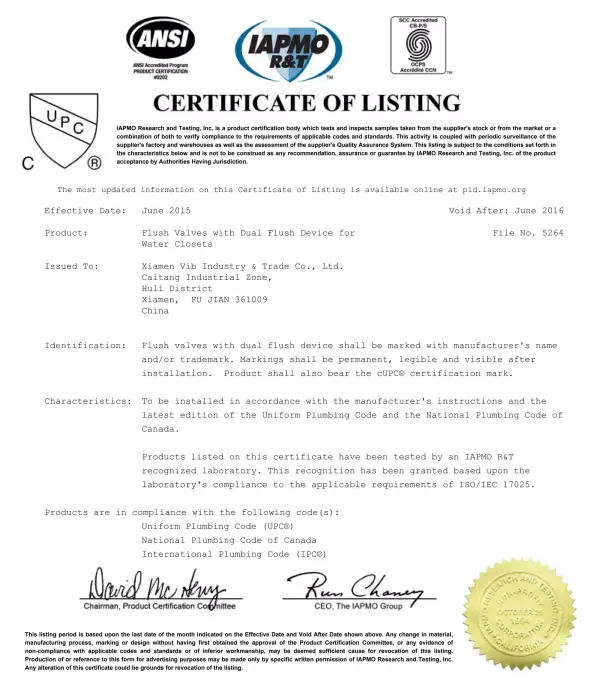

UPC(Uniform Plumbing Code)

WRAS(Water Regulations Advisory Scheme)

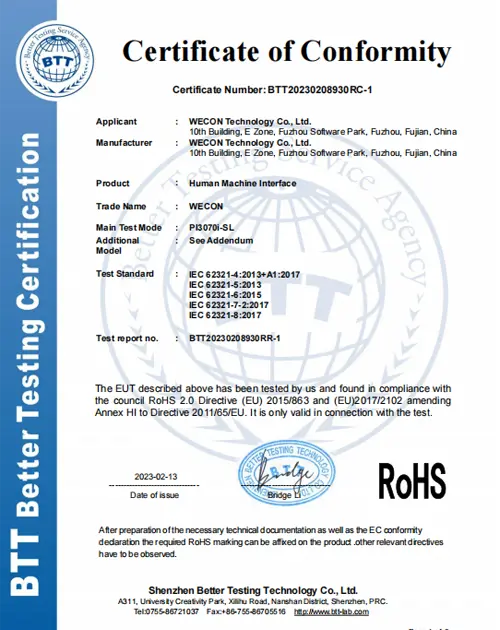

RoHS(Restriction of Hazardous Substances)

In-Process Control

Inspect critical dimensions and surface roughness after milling, turning, or stamping processes.

Check fitting gaps, thread engagement, and the proper positioning of sealing components during pre-assembly.

Conduct First Article Inspection (FAI) for the initial piece and each production batch.

Functional & Leak Test

Conduct static pressure testing on fully assembled faucets, maintaining the specified pressure for a defined period.

Perform dynamic cycle testing to simulate repeated handle operation (on/off cycles).

Check flow rate and temperature mixing performance, including hot–cold switching and outlet stability.

Final Inspection & Packing Check

Conduct AQL-based random sampling to verify appearance, functionality, accessories, and labeling.

Check packaging strength, internal protective materials, and completeness of accessories and manuals inside the carton.

Confirm pallet labels, carton markings, packing list, and batch traceability information.